Company DataCOMPANY DATA

Corporate history

| 1967 | Daikyo Painting LTD. established |

|---|---|

| 1976 | Daikyo Corporation incorporated(Incorporation) |

| 1984 | Cabin painting started (production line was placed) |

| 1985 | Imae No.2 Plant completed |

| 1989 | Cation electrodeposition coating started |

| 1991 | Kawasaki Office was set up |

| 1992 | Assembly of driver's seats for construction machinery started |

| 1993 | Assembly of garbage collection trucks started |

| 1994 | Completion of Plant No. 1 headquarters relocation |

| 1995 | Resin painting started, and production of garbage treatment equipments started |

| 1996 | Construction of Plant No. 2 at the Company’ s headquarters completed |

| 1997 | Komatsu Quality Control Award was awarded |

| 1999 | ISO 9002 certification was acquired(transferred to 2015 version of ISO9001 in July 2018) Thin metal sheet processing started on a full-scale basis, and 1,000-ton pressing machine introduced Large-scale cation electrodeposition coating & painting facility introduced |

| 2001 | ISO 14001 certification obtained (renewal was completed in July 2018) |

| 2002 | Powder coating facility introduced |

| 2003 | Shandong Cab Co., Ltd. (SDC)established (China) |

| 2004 | Construction of Plant No. 3 at the Company’ s headquarters completed |

| 2005 | Large-scale black cation electrodeposition coating & painting facility introduced |

| 2006 | Daikyo Corporation(Thailand) Ltd. established (Thailand) |

| 2007 | Daikyo Machinery Shandong Co., Ltd. established(China) |

| 2011 | Daikyo Machinery Shandong Co., Ltd. Plant completed the second phase |

List of facilities

| Name of machine | Capacity | Quantity of units |

|---|---|---|

| Electro-deposition coating line (ivory) | Dimensions of item to be coated: 1,500 x 4,000 x 2,000 | 1 |

| Electro-deposition coating line (ivory) | Dimensions of item to be coated: 1,500 x 4,000 x 2,000 | 1 |

| Coating equipment (powder) | Dimensions of item to be coated: 1,500 x 4,000 x 2,000 |

1 |

| Coating line (melamine) | Dimensions of item to be coated: 700 x 2,500 x 1,500 |

1 |

| Coating peel-off blasting machine | φ1,500×2,000 | 1 |

| Cab seat assembly line | 4,000 units/month | 2 |

| 3-D laser cutting machine | 2.5kW, 3,100 x 1,900 x 800 | 1 |

| 2-D fiber laser processing machine | KFL2051 3.0kW | 1 |

| 2-D fiber laser processing machine | KFL3051 3.0kW | 1 |

| Shears | SHS 255 | 1 |

| Fully automatic band sawing machine | SSP-400D | 1 |

| Deep drawing hydraulic press | 1,000t | 1 |

| Press brake | PBZ 1753 | 1 |

| Press brake | PVS 8525 | 2 |

| Welding robot | 10 | |

| NC spot welding machine | 80kVA, 2,000 x 1,000 | 1 |

| Overhead traveling crane | 1t~2.8t | 18 |

| Overhead crane | 20t | 1 |

| shower test unit | 1 | |

| Handling Robot | 1 | |

| CAD 2-D,3-D | MICRO CADAM, Creo | 11 |

| CADMAC | NEX | 1 |

| CADMAC | BS32 | 1 |

| Angle cutter | 1 | |

| 3-D measuring instrument | 1 | |

| 3-D scanner | 1 | |

| Deburring machine | Maximum processing dimensions 1,300mm | 1 |

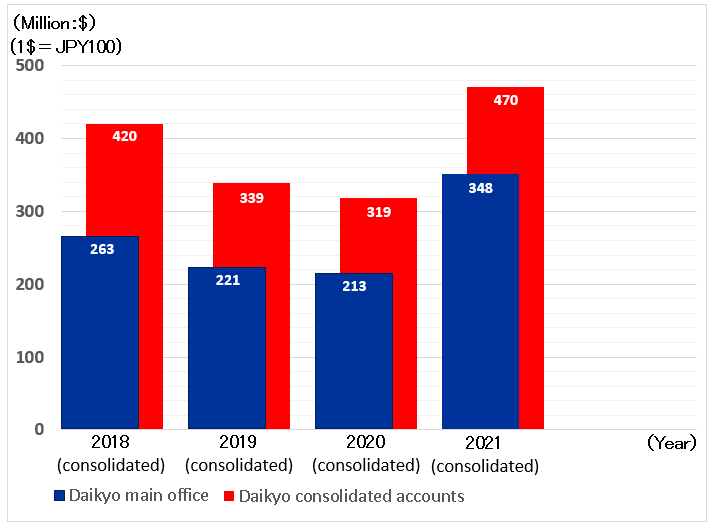

Revenue bar chart